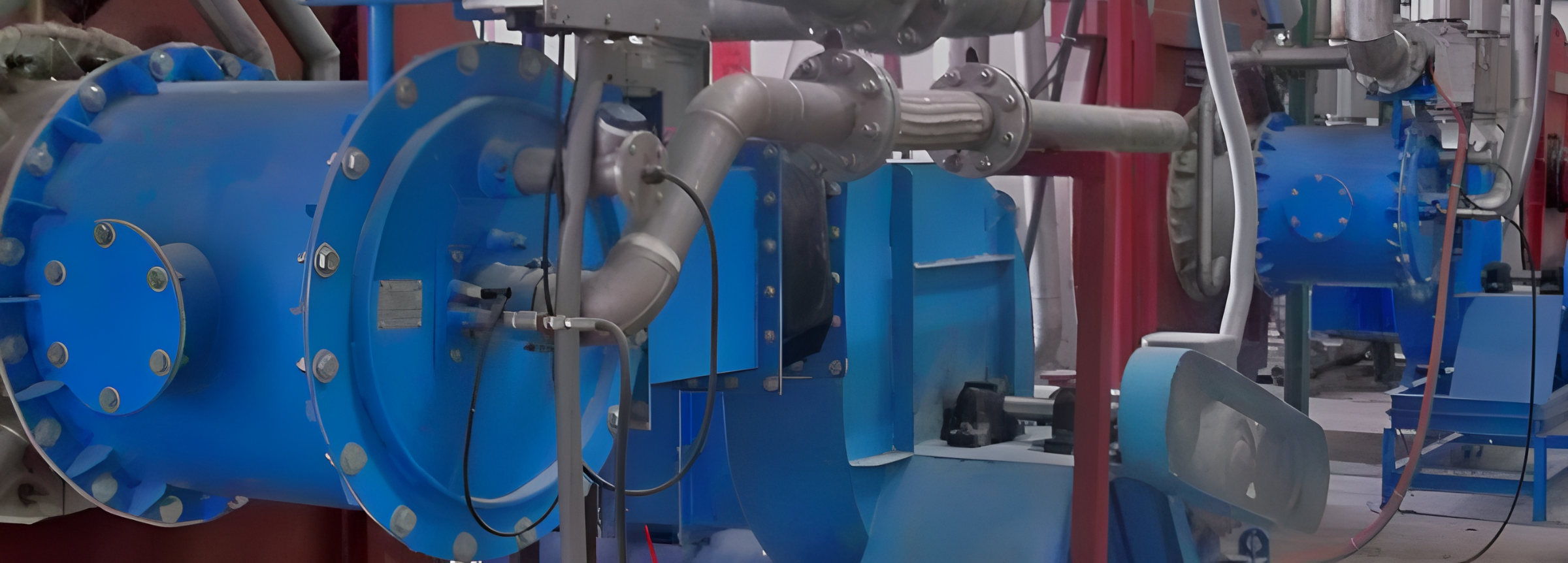

Enclosed Biogas Flare Systems

The purpose of a flare is to burn off excess biogas from the system in order to prevent harmful methane gas from being released directly into the atmosphere. As 1kg of methane has an impact equal to nearly 21kg of CO2, all BKE enclosed biogas flares are specifically engineered for more than 90% methane destruction efficiency in order to ensure that as little methane escapes into the atmosphere as possible. All of our Flare systems are CDM compliant and installation of a BKE clean biogas system qualifies your company for CDM Carbon Credits. This is an opportunity to reduce your carbon footprint while utilizing BKE technology to reduce your operating costs.

Key selling points of BKE Enclosed Biogas Flare Systems:

- 90% Methane Destruction

- Cost Effective

- User-Friendly

- Safe & Reliable

- Complies with EU Safety Standards

- (Inclement) Weather Operational/Resistant

- Constant Operation

- Low Electricity Consumption

- CDM Compliant

- Carbon Credit Gain

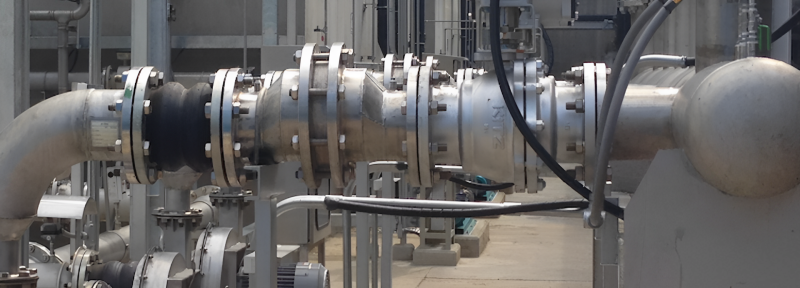

BKE designs and fabricates flares to accomplish your needs. Small or large, standard or custom, all are designed to meet your specific requirements. Our products are recognized and in operation throughout S.E. Asia, Europe and the U.S.

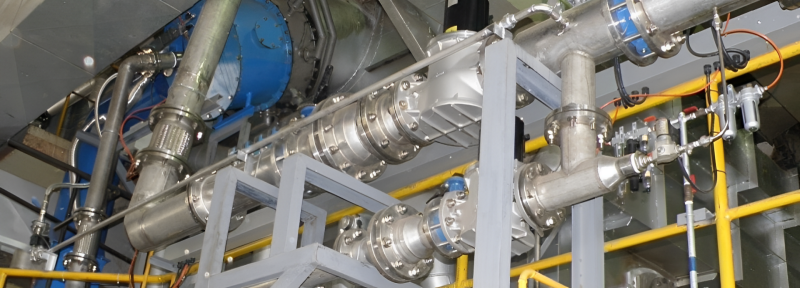

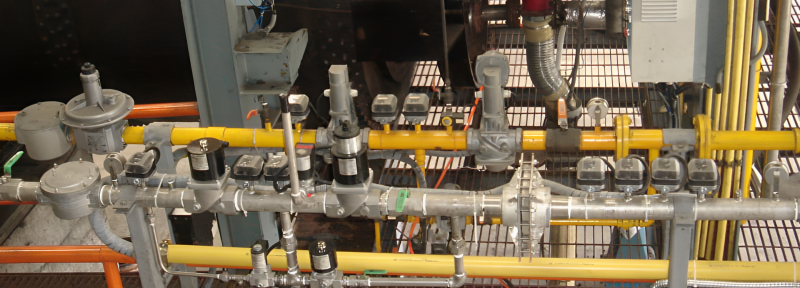

BKE combustion technology coupled with correct material selection and our unique designs, allows our flares to be in operation constantly throughout inclement rain and wind conditions. Safety is our priority, thus the flame arrester, flame detector and the automatic burner control with safety shut-off valve are always our standard components. Corrosion by hydrogen sulfide contained in biogas is a key consideration, so all contact areas with corrosive elements are constructed of high-grade stainless steel. Additionally, the biogas-train is designed to allow a low gas pressure supply in order to consume less electricity by the blowers or pumps.

With more than 10 years of experience and references, BKE ensures that its clients benefit from the best combustion results with the highest safety standards and greatest gain of Carbon Credit.