Metal Treatment

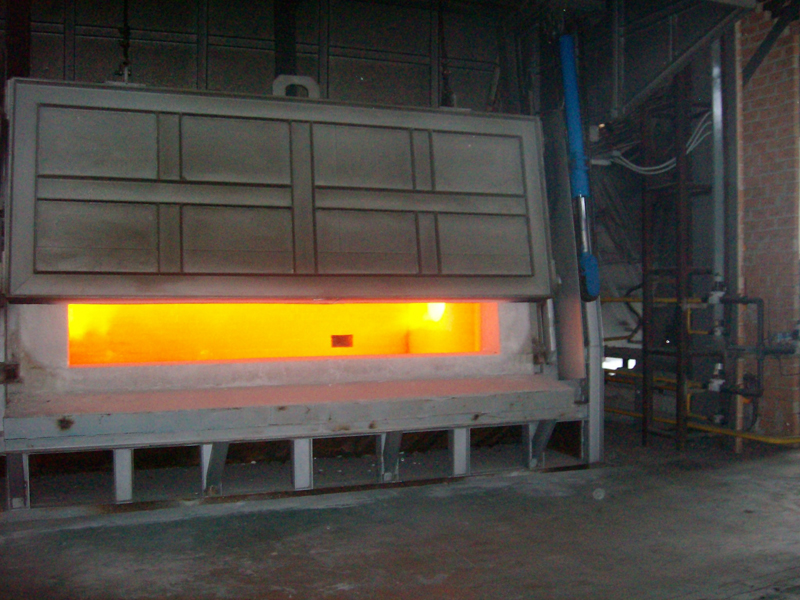

BKE Metal Treatment Furnaces are designed to utilize either burners or electricity with temperatures reaching up to 1,400°C and are used in a wide range of treatment applications.

Such as:

- Aluminum Melting Furnaces

- Die Casting Machines

- Heat Treatment Furnaces

- Annealing

- Tempering

- Hardening

BKE Aluminum melting furnaces reach temperatures above 800°C. Our die-casting machines have a load capacity near 300kg or the melting furnace with a 50-ton capacity or more. Tempering or annealing, which need precise programmable setting temperature controls for either heating or cooling lamps or soaking, are accomplished with the BKE stress relief furnace. The maximum 2°C of temperature deviation from the set point and a maximum 5°C temperature variation of loading surface are our standard design.

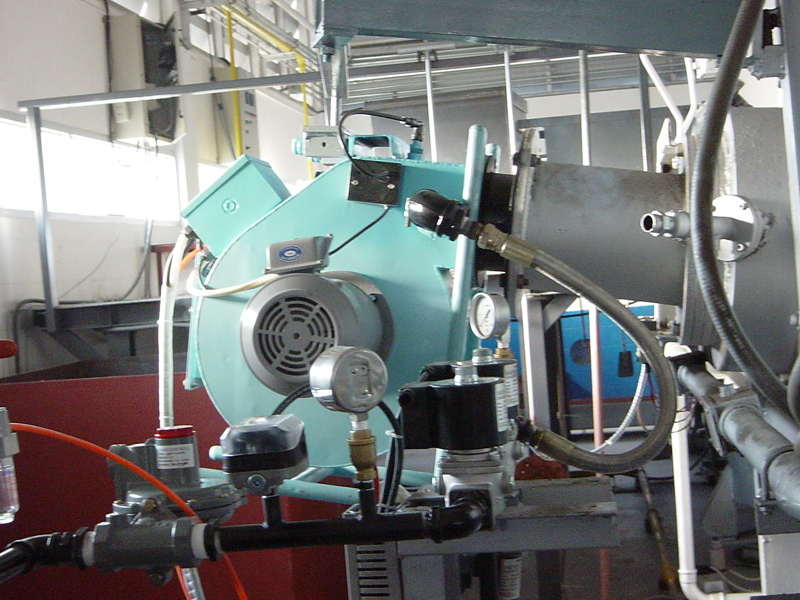

The BKE combustion furnace is our specialty and offers sequential pulse firing whereby each burner gives pulse fire at different periods of time in order to allow back and forth convection. The combination of this pulse firing and high velocity burner technology have proven to allow less fuel consumption and better thermal distribution than the conventional modulating fire burner technology. BKE also offers a multi-zone temperature control to make sure that there will be even temperatures of large size metal loads. We design and construct to handle any shape or sized metal, whether long or tall, square or round. We fabricate to order, including temporary furnaces at factory or remote sites.