- Effectively removes condensate from the system to allow for maximum biogas utilization

- Increased combustability means less wasted biogas

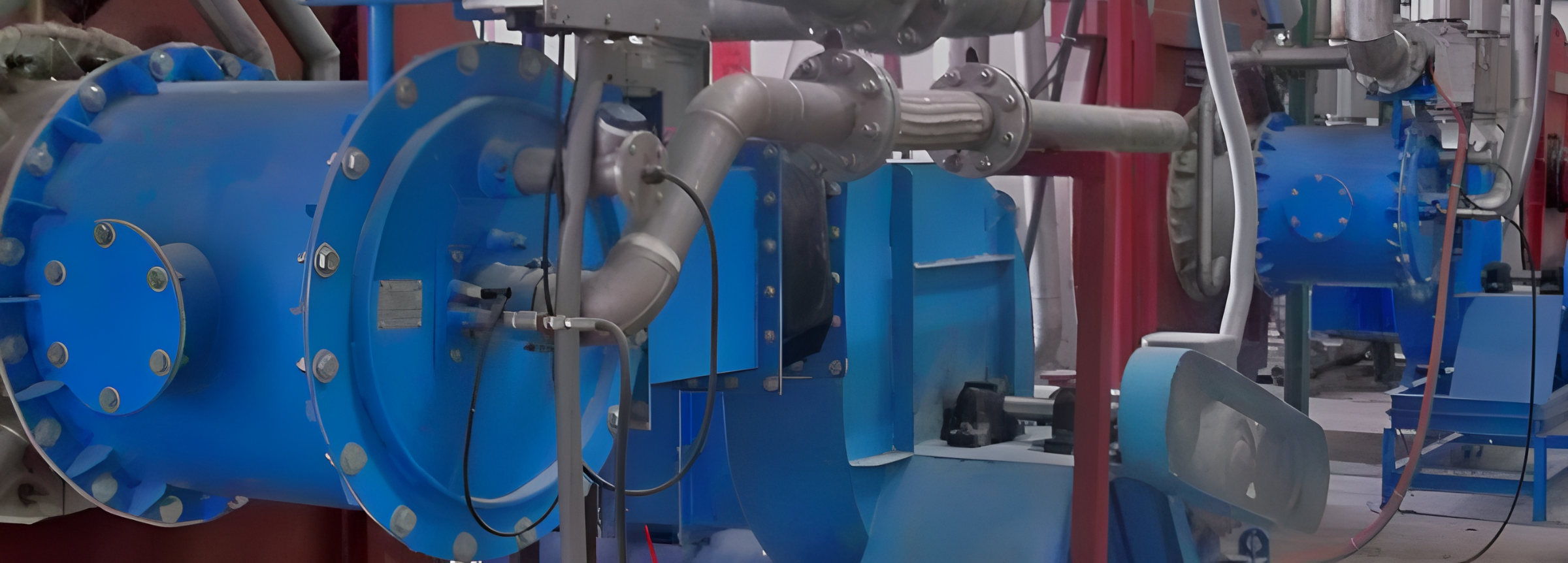

Biogas Dryer

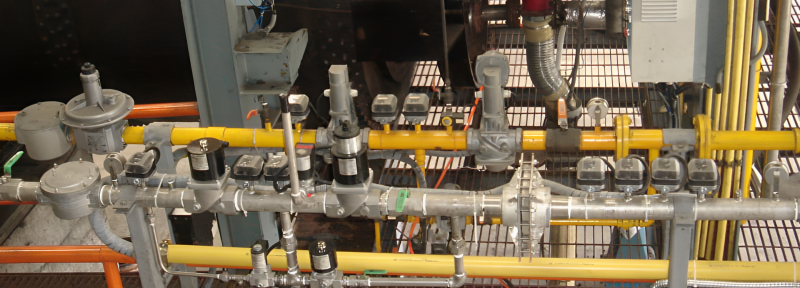

BKE gas supply & safety systems, also known as ‘gas trains’ are a critical component engineered into all of our burner systems. The key purpose of the gas train is to safely deliver the combustible fuel to the burner at a desired flow rate, while continually checking (and re-checking) the system to ensure constant and reliable flow and pressure.

BKE biogas trains contain a combination of safety and delivery components including:

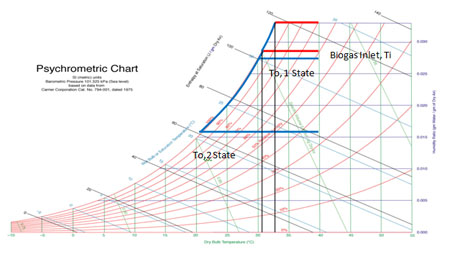

BKE biogas dryers are machines for reducing water content in biogas. The water content can be a form of vapor or liquid (condensate). The water vapor content in the biogas can be calculated as they are in the form of atmospheric air. Therefore the psychometric chart is applied to find the amount of water vapor in the biogas by the units of relative humidity (%RH) or absolute humidity (kg water/kg dry biogas). As long as there is no specific psychometric chart for biogas, the chart for atmospheric air is close enough and applicable.

As you remove water from the biogas you reduce the biogas temperature below the dew point. At that reduced temperature, some vapor will condense and turn to liquid (condensate). Please note that the lower the temperature, the more condensation may take more electricity consumption.

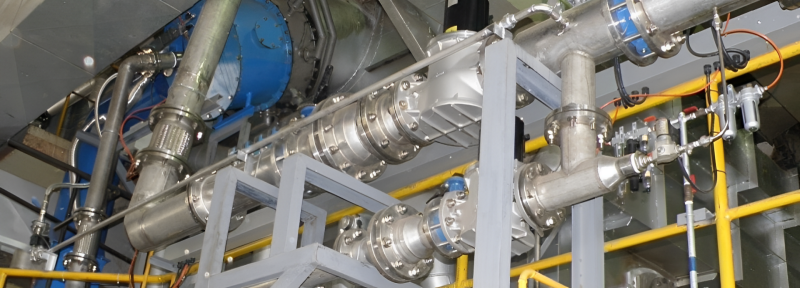

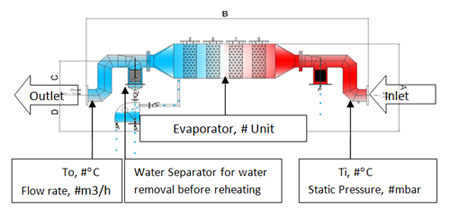

To remove condensate from the biogas handling system, a water separator is used as shown in the diagram below.

After the biogas temperature is reduced, the relative humidity is still the same at 100% RH but the absolute humidity is reduced to 0.015 kg water/kg dry biogas. The balanced amount of water is the excess water of 0.048160-0.015 = 0.03396 kg water/kg dry biogas. The excess water or condensate will be removed by the water separator. So the stage after the water separator is still keeping the relative humidity at 100% RH but minus the excess water.

The next stage is to recover the biogas temperature by reheating which can be done by natural heat transfer depending on the ambient temperature, the length of the biogas supply piping and the pipe wall conductivity. We can also force reheating by using blower(s) to boost the biogas pressure.

The following chart shows the saturation points relative to Humidity and Temperature.